How 4Pack Can Help Your Business when Launching A New Product

When it comes to launching a new product, there are crucial aspects that businesses must address. In particular: packaging regulation compliance, sustainability management, label and artwork accuracy, and precise product and packaging specifications. With 4Pack’s comprehensive suite of solutions, these challenges become easier to tackle, enabling businesses to streamline processes and achieve compliance effortlessly while optimising sustainability practices.

Compliance with packaging regulations can be a complex task. However, 4Pack’s intelligent software simplifies the process by automating the tracking and management of regulatory requirements specific to your industry and target markets. Stay informed about the latest regulations and maintain compliance throughout your product’s lifecycle, reducing the risk of penalties and allowing you to launch your new product with confidence.

In today’s market, sustainability is paramount. 4Pack’s solution empowers businesses to adopt a proactive approach to sustainability management. Evaluate the environmental impact of your packaging choices, optimise materials usage, and minimise waste with our platform. Identify sustainable alternatives and monitor your progress to enhance your brand’s reputation, attract environmentally conscious customers, and contribute to a greener future.

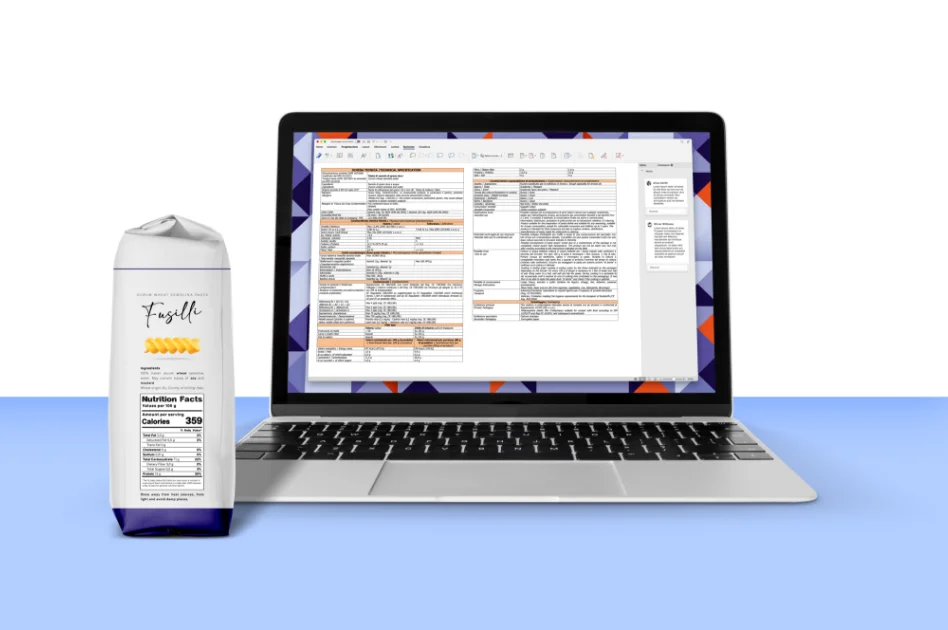

Accurate labels and artwork are crucial for product success. With 4Pack, you can centralise label and artwork management, ensuring version control, consistency, and compliance with regulatory guidelines. Collaborate seamlessly with stakeholders, streamline the approval process, and reduce errors. Efficiently managing labels and artwork enhances brand consistency and speeds up time-to-market, giving your new product a competitive edge.

Precise product and packaging specifications are essential for quality control and supply chain efficiency. 4Pack’s solution provides a centralised repository for all specifications, ensuring data integrity and accessibility across teams. Automate workflows to streamline specification creation, review, and approval processes, minimising errors and delays.